There’s been a lot of interest in my rainbow drop swirl (Tutti Frutti) soap recently, so I thought I’d put together a little pictorial tutorial for anyone who’s interested in how it’s done (I really, REALLY should start making videos shouldn’t I?).

Many of you will already know how big a fan I am of the drop swirl technique. Almost all of my core range is made using either a full or partial drop swirl, and Tutti Frutti is no exception. I made another couple of batches recently, and took some photographs along the way…

**Please make sure you’re familiar with the basics of soapmaking before you try any advanced swirls (Soap Queen is a good place to start) and always wear protective clothing / gloves / goggles. Safety first!!**

I generally make soap at room temperature, so I’ll mix up the lye solution in advance and put it to one side to cool down (I don’t discount the water for this one). I’ll also melt the hard oils and butters and combine them with the liquid oils and butters and allow them to cool down to room temp.

Next I measure out the seven different micas straight into the pouring jugs (actually here you’ll see six different micas and one liquid colourant. It’s notoriously difficult to get a good red in CP soap, but I use a liquid colour from Gracefruit which is rather good. They appear to be out of stock of the red at the moment, but hopefully it’ll be back in soon.)

Next I add my fragrance oil to the room temp oils and butters. Many people add their fragrance AFTER adding the lye and tracing the soap, but my preference is to add it before.

I then add a couple of teaspoons of the fragranced oils to each jug of mica and get them well blended. I know it’s common practice to skip this stage and simply add the traced lye batter directly onto the powdered mica (or add the powdered mica directly to jugs of traced batter), but I don’t always use a stick blender and this way I know I can get the colour incorporated well just by giving it a good mix with a spatula.

I get my moulds ready – notice my high-tech method of stopping the mould sides from bowing inwards 😀

And then we’re ready to go… I mix the lye water into the tub of (already fragranced!) oils and butters, and share the soap batter out equally into the seven prepared jugs. It would appear I forgot to get a photo of that stage – sorry! What we’re looking for is a really light trace as the soap will thicken up during the pouring process. Personally I don’t stick-blend this soap AT ALL. I find that by the time I’ve mixed up all the colours thoroughly it’s already at a light trace, but this will very much depend on how quickly your particular soap recipe traces and which fragrance you’re using. I’ve even found that certain micas can inhibit trace, so there are many different factors involved. It’s a case of using your judgement and, to be honest, trial and error.

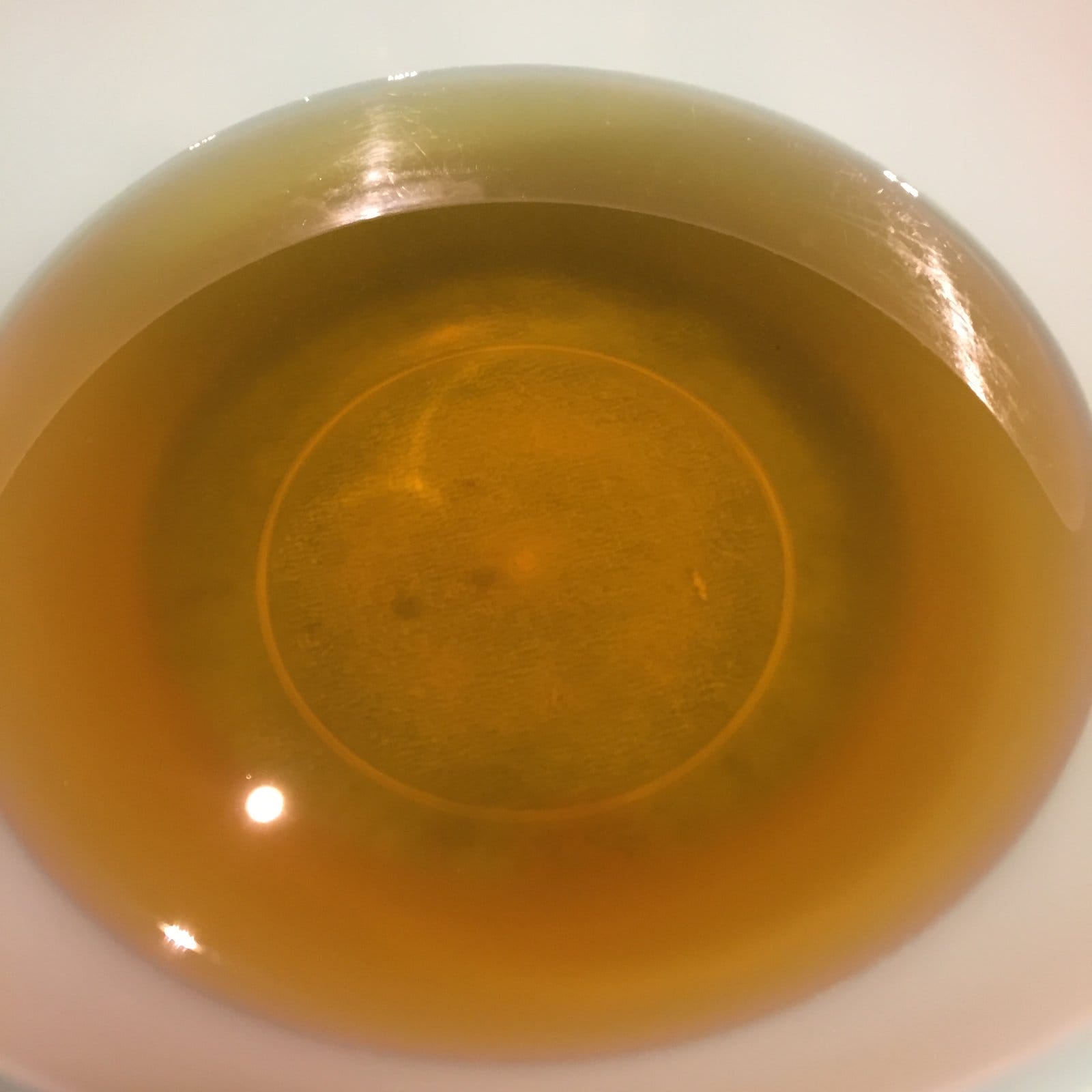

Next comes the pour. First in this time was yellow:

What’s crucial for a nice drop is the height from which you pour the soap in to the mould. At the early stages my jug is quite close to the bottom of the mould as I pour a line of soap along the length of it. Here’s the next couple of pours:

Once the bottom of the mould has been covered with soap, I start to raise the jugs a little higher as I pour, so that the soap drops into the previous layer, rather than sit on the top of it. It’s very hard to give a precise height as it very much depends on how thick your soap batter is (the thicker it is, the higher you’ll need to drop it from)

I try to make sure I pour from the jugs in the same order on each round of pouring, and also try to make sure I’m not pouring a colour on top of the same colour in the mould.

I keep pouring until the moulds are full:

By this stage the batter is quite a bit thicker than when I started to pour, and looks none too tidy, but it doesn’t really matter once I start adding texture to the top:

And the finished item:

I generally leave soap in the mould for 48 hours before I unmould and cut:

And that’s it. It’s cured for 4 weeks, bevelled and tidied up, cured for another 2 weeks then released for sale.

Some time ago I started using the Instagram hashtag #dropsaretops for some of my photos – please use the tag to share your own drop swirls and make this drop swirl junkie very happy 😀

For the last couple of years, from March through to November, I’ve given a weekly soapmaking talk to holidaymakers staying in a local hotel. It’s an opportunity to get paid to rattle on about my favourite subject, and if I’m lucky I’ll sell a few bars as well. Win-win you might think? Well yes, these days I absolutely revel in it, but there’s no denying that the first few times I was really quite nervous. With that in mind I thought it might be helpful to others if I were to note down some of the things I now always do to ensure I give a successful soaping talk.

For the last couple of years, from March through to November, I’ve given a weekly soapmaking talk to holidaymakers staying in a local hotel. It’s an opportunity to get paid to rattle on about my favourite subject, and if I’m lucky I’ll sell a few bars as well. Win-win you might think? Well yes, these days I absolutely revel in it, but there’s no denying that the first few times I was really quite nervous. With that in mind I thought it might be helpful to others if I were to note down some of the things I now always do to ensure I give a successful soaping talk.