Or perhaps, this week, the title should be: Yr Wythnos Mewn Sebon: 4ydd o Fawrth, ’18, because this week, on Wednesday 1st March, we celebrated St. David’s Day, or Dydd Gwyl Dewi as we know it. St David is the patron saint of Wales, and as a good Welsh girl, I felt I really should include a little Welsh language, and some daffodils, in this week’s post 😀

Of course, Welsh Cakes had to be made too. There were many, many more than this, but by the time I thought to take a photo the pile had depleted somewhat:

Other than St David’s Day, the most notable thing this week has been the weather. There’s been a LOT of weather. The Beast from the East blew down from Siberia, and, along with Storm Emma, caused chaos and crisis the length and breadth of Britain. We got plenty of snow here in our little corner of Snowdonia, but to be honest weren’t too adversely affected. In fact, the only inconvenience for me was the fact that delivery lorries couldn’t get through so I ran out of sodium hydroxide, despite having ordered it in plenty of time. Ho hum….

On Monday, I made up a big, four loaf batch of Traeth Craig Du (Black Rock Sands) soap. This one’s such a doddle to make as I don’t have to worry too much about keeping the batter fluid for the swirls – it’s just a simple three layer soap. Here it is in the mould:

And freshly cut:

I also made seven dozen bathbombs this week, six large and six small of each fragrance. They’re not huge sellers, but they’re slowly growing in popularity, and I’ve had some wholesale orders through, so I thought it was time to start building up stock levels again. I made, clockwise from top left, Bewitched, Lavender, Clarity, Welsh Rose, Oatmeal, Milk & Honey, Sugar Drops and Serenity (in the middle)

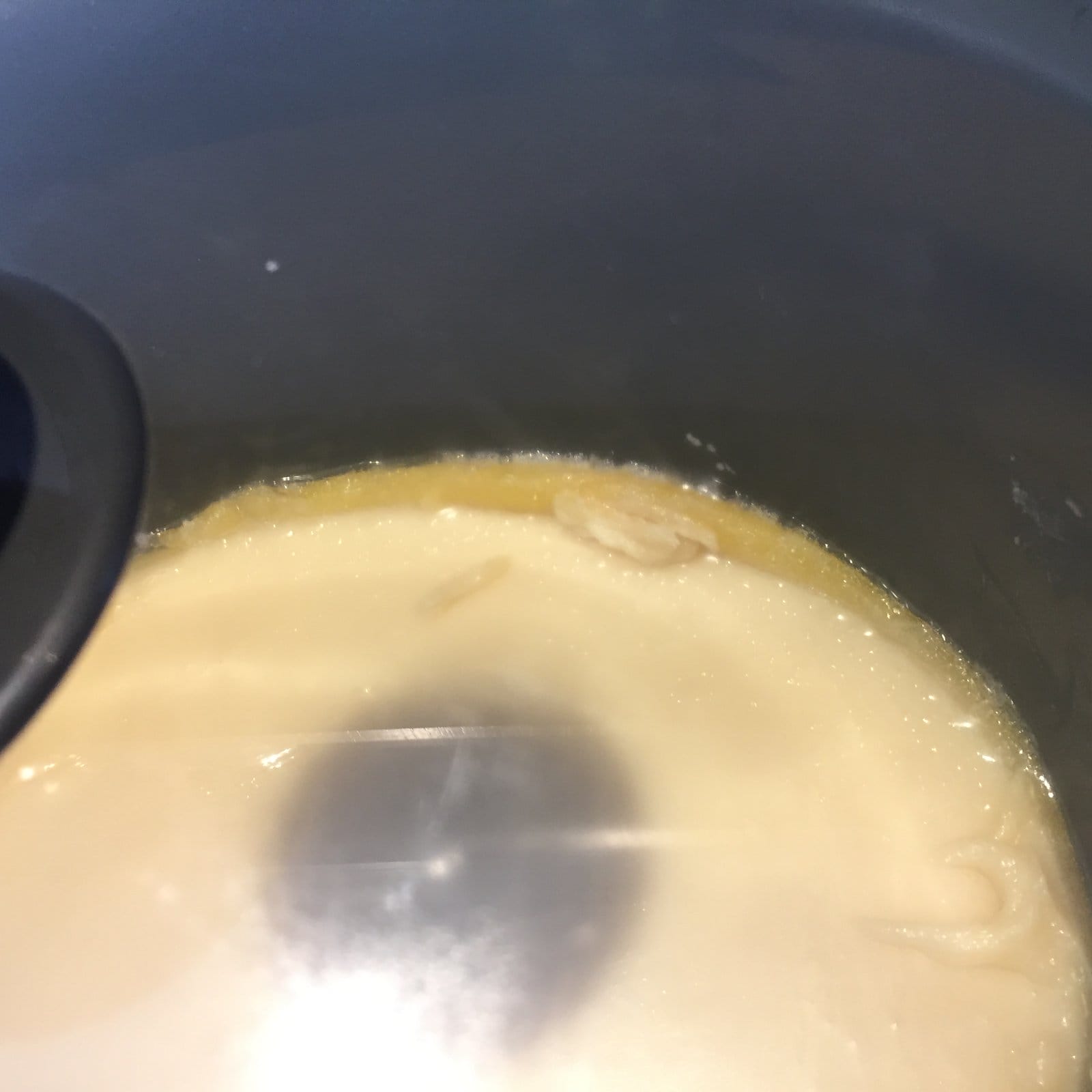

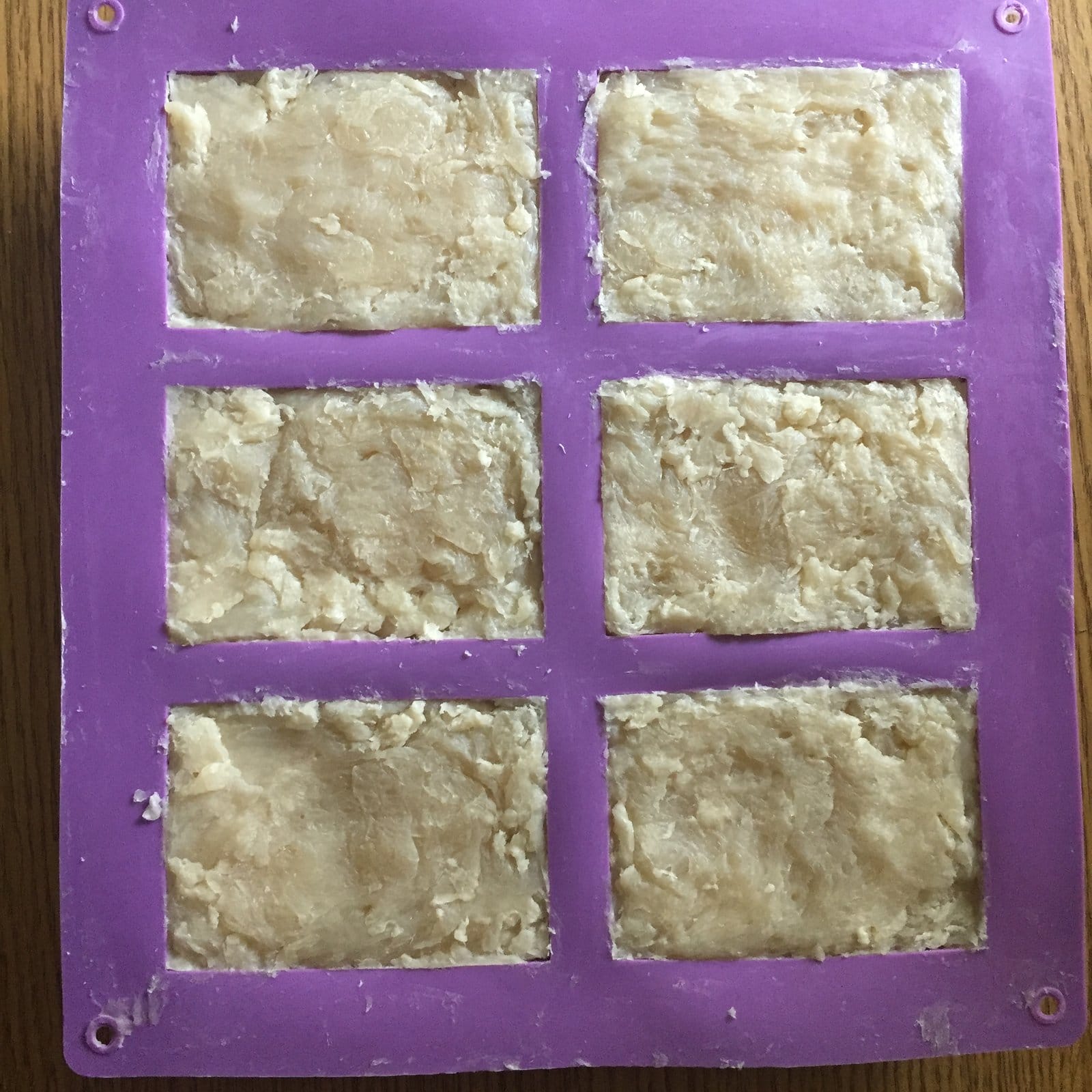

The only other thing of note that I’ve done this week, other than the usual day to day mundane stuff, is make Hot Process soap. I finally got round to getting out that slow-cooker that I bought before Christmas to make up a batch of solid shampoo. I was surprisingly happy with the results, especially for a first attempt:

These bars are half sized, as I’m planning on sending most of them out to friends & family for testing once they’ve cured a while, and I’m looking forward to hearing what people think of them.

I was due to be at a craft fair today (Sunday), but unfortunately it was postponed because of the adverse weather conditions – it’s been rearranged for a couple of weeks time so nothing’s been lost.

Oooh yes, and I finally hit 500 followers on Twitter. It’s been a long time coming but I’ve been putting a bit more effort into it and it seems to be paying off slowly. Very slowly!

As always, thanks for reading. I’m going to try to devote some time to my (not imaginary, I promise) website this coming week, but don’t hold me to it!!

Vickx